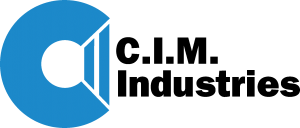

Erosion occurs when winds or water interact with soil and rock, causing the affected earth to wear away. The most common example of erosion is at the beach, where tide patterns cause water to move up onto the shore and away from the shore, dragging the sand out to sea and changing the landscape.

To remedy this, communities have built retaining walls that follow parallel to the shoreline to help stop surface and subsurface erosion. While the beach may be the most thought of place where erosion occurs, it also happens onshore. Torrential downpours can wreak havoc by causing flooding and extreme soil erosion. Like beach erosion, there are ways to mitigate this issue.