Winter is here, and you may have surfaces that need coverage despite the cold weather. It is important to understand the environmental conditions and limitations of cold weather application before proceeding with the application of any coating.

Review the cold-weather fluid-applied application instructions for detailed application guidelines. However, the application guidelines alone will not paint the full picture. Follow along for professional advice on applying in the (cold) field.

How to apply CIM material in cold weather

"Cold weather application" refers to any application where the surface temperature of the substrate dips below 50 °F. Working in these conditions takes similar considerations to standard applications.

Heating

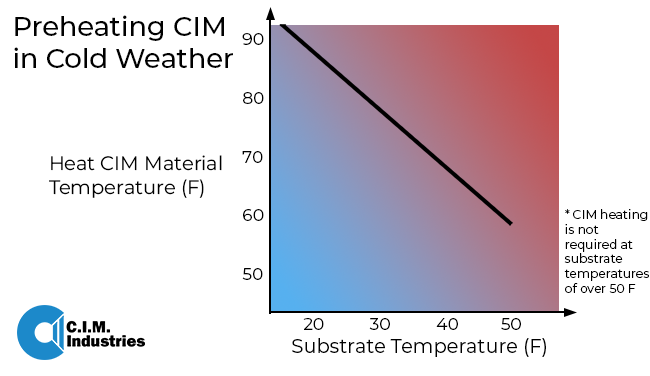

Material temperatures should ideally be 70F. At colder temperatures, heating the materials is advised to help with the workability of the coating. A good rule of thumb: for each degree below the 50-degree threshold, ensure that the CIM material is heated at least one degree above 60 °F.

Viscosity

The material's temperature will drop as it is applied to the substrate. Colder material temperature causes increased viscosity/thickness. This increased viscosity makes it difficult to spread the longer it takes to apply. Additionally, vertical surfaces may experience dripping in the material as it cools, resulting in a lower thickness of the remaining material.

Cure Times

Slower cure times affect vertical application (limiting the thickness of materials on walls or side panels due to the risk of dripping/sagging). To put this in context, CIM products typically cure within a few hours at 70 °F. In colder weather applications, Cure times will be longer and it is not uncommon to not be tack-free for 4 to 8 hours at temperatures of 50F and below.

How Cold is Too Cold? Limits to Cold Weather Application

It's essential to choose the right CIM material for your job. CIM 1000, 1061,1000TG as a stand-alone product can be applied at temperatures as low as -20 °F.

However, It's recommended that porous substrate applications use EMT epoxy primer before the CIM material is applied. This helps mitigate the risk of outgassing and delamination due to surface moisture.

EMT Epoxy Primer can only be applied to substrates at a minimum surface temperature of 40 °F or higher. So for temperatures below this threshold, CIM EMT Primer cannot be used.

4 Methods of Applying CIM Below 40 °F

We do recognize that postponing for favorable conditions isn't always possible. Sometimes a job needs to get done when it needs to get done, even if that's during substantially cold weather. Let's break down a few application scenarios you can expect during sub 40 °F conditions:

- Applying CIM Over Non-porous Substrates

- Applying CIM Over Concrete Surfaces with Primer

- Applying CIM Direct to Concrete (No Primer)

- Applying by Using Heat

1) Applying CIM Over Nonporous Substrates (Metal Application)

Cold weather CIM application over metals is a fairly straightforward process. CIM coatings can be applied at temperatures as low as -20 °F. Follow along with our cold weather application guide, and be mindful of longer cure times and greater occurrence of runs and sags.

It is important for any cold weather application to ensure that the temperature of the substrate is at least 5 °F above the dew point, and this can be more challenging at colder temperatures.

The CIM Bonding Agent will take longer to flash off in cold weather and must evaporate before application of CIM coatings. Check out our video guide for a detailed breakdown of standard temperature non-porous applications.

Be sure to take into consideration the elongated curing period as CIM membrane takes far longer to set in cold temperatures than standard temperatures. Here are some helpful guides for CIM applications:

2) Applying CIM Over Concrete (With Primer)

Substrate temperature will impact the application method and restrict application below 40F.

Application Above 50 °F

CIM application within this range is considered a standard process. The cold weather application guidelines should not be considered for surface temperatures in this range, other than preheating CIM.

Applications Ranging From 50-40 °F

Follow the instructions on the cold weather application guide. The EMT Primer requires an induction time before application. For applications in this temperature range, the induction time is a minimum of 15 minutes. The induction time is required to allow the chemical reaction to begin and limit amine blush on the surface which negatively impacts adhesion.

Applications Below 40 °F

Epoxy primer cannot be used when substrate temperatures are below 40 °F. If application must take place in this temperature range and the area cannot be heated above 40 °F (more on that below), it is critical to closely monitor environmental conditions and ensure that temperatures remain above 40°F at all times during the curing process

3) Applying CIM Over Concrete (Direct, No Primer)

It wasn't all too long ago when applying CIM membranes without a primer was standard procedure, but this process has risks.

EMT epoxy primer is a moisture-mitigating primer. Applying directly to concrete has the innate risk of delamination and outgassing. The application requires both surface moisture measurements and vapor transmission testing in multiple areas before the job. CIM surface moisture should be below 5% and vapor transmission less than 5 lbs per 1000 sq ft 24 hrs. These tests are required over multiple areas as these readings may vary from spot to spot.

4) Applying by Using Heat

In some instances, a contractor can isolate the substrate with tents or other methods of climate control, thus raising the temperature to support the use of EMT Primer. There, applicators pump artificial heat into the space through one of a few methods. This should only be performed with electrical heat or indirect heat.

Petroleum-based heaters can only be used if the unit is designed for indirect heat. Standard fossil fuel heaters (like torpedo heaters) introduce moisture and carbon residue into the environment. This can cause problems with adhesion and delamination of CIM membranes.

Remember, heaters will probably need to be shut off several hours before application. The substrate temperature must be declining during the application of both EMT and CIM. If a surface rises in temperature while the membrane is being applied, outgassing can occur as the concrete attempts to "breathe out" through the membrane. It may take several hours for the substrate temperature to begin declining after the heat is turned off. Take routine surface temperature readings to determine when the application should start.

Tenting is an option for creating a closed system (and optimal temperature thresholds for the primer), but it can be space-limited and inconsistent. If you opt for a tent, always be sure to practice safe application in enclosed spaces.

In summary, cold weather applications can be successful when the proper considerations are met. Keep a copy of the cold weather application guidelines on hand for easy reference. If you have any questions, CIM's team of technical support is just a phone call away. Reach out in the comments or select the Contact Us button to receive the support you need.

Chase Corporation's team of technical representatives can assist you with CIM's two-part urethane fluid-applied liners and coatings and pipeline product information to meet your application needs; please contact us.