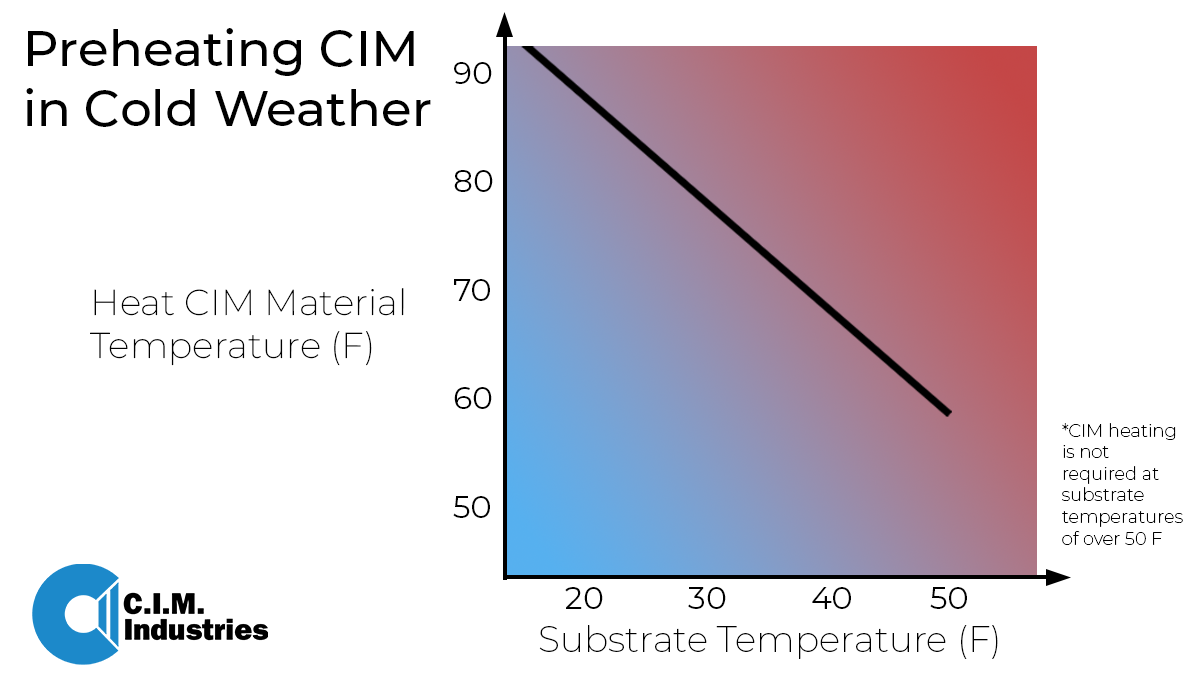

Winter is here, and you may have surfaces that need coverage despite the cold weather. It is important to understand the environmental conditions and limitations of cold weather application before proceeding with the application of any coating.

Review the cold-weather fluid-applied application instructions for detailed application guidelines. However, the application guidelines alone will not paint the full picture. Follow along for professional advice on applying in the (cold) field.