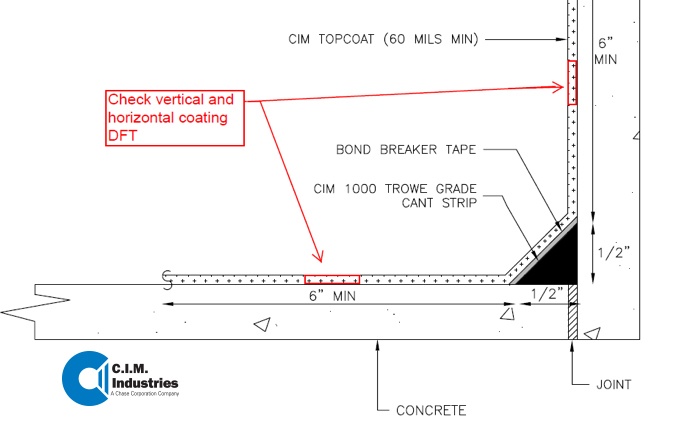

The most common method employed to tie into an existing hot rubberized asphalt system is to use more hot applied asphalt. This involves using hot kettles and can present some jobsite challenges, such as mobilization issues, safety concerns and foul odor. Cold-applied membranes can address all these concerns. Consult the manufacturer of the cold liquid-applied membrane to verify approval of application procedures. Manufacturers may be able to offer case histories, detail drawings, and application guidelines to help provide technical support needed for tie-in methodology.

Most methods, however, will include the steps listed below.