It is critical that the appropriate amount of CIM Activator be mixed with the appropriate amount of CIM Premix. Therefore, each CIM product comes packaged with pre-measured quantities of Activator and Premix.

Each pre-measured container has a color-coded label to assist with identifying the appropriate Premix and Activator.

Related article:

How to Select the Right CIM Activator & Premix

Requirements:

-

One-gallon can of Premix are to be mixed with the appropriate bottles of Activator, and five-gallon pails of Premix are to be mixed with the corresponding jugs of Activator.

-

One and only one bottle/jug of Activator must be used for each can/pail of Premix product.

-

For 5 gallons pail a ½· drill (at least 5 amp and 500-900 rpm) and appropriate mixing paddle should be used to mix all CIM products. One gallon kit can use a smaller drill.

-

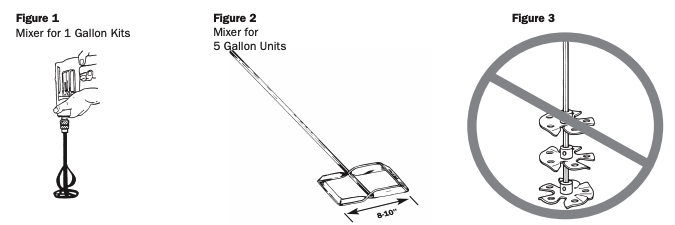

One-gallon cans should be mixed with a 3" spiral blade (see Figure 1) and five-gallon pails with an 8" mud mixer (see Figure 2).

-

All products are to be mixed for three minutes.

Watch the explainer video

To assure proper and thorough mixing with minimal manpower, C.I.M. Industries recommends using a Mixing Jig and Timer (mixing Jigs can only be used for 5-gallon kits and cannot be used for CIM 1000 TG). When using a Mixing Jig, cut the mixing paddle shaft so the bottom of paddle is between one quarter inch and three-quarter inches from the bottom of the pail. Different CIM Premix products may have different pail heights.

More requirements:

- Fan blade or rod style mixers are not to be used (see Figure 3).

- Spiral mixers may be used only for one-gallon cans (see Figure 1).

- Never mix CIM products by hand!

- Mixing Jigs should not be used on CIM 1000 Trowel Grade.

- Do not thin! If material is too viscous, it should be warmed to 75 F to 95°F.

- Do not mix water or air into the pail.

- CIM Activator is not a catalyst! Do not add more or less than one bottle of Activator to each pail of Premix! Changing the ratio will alter coating or liner performance.

- Keep Premix and Activator at 75°F to 95°F for lower viscosity and easy mixing.