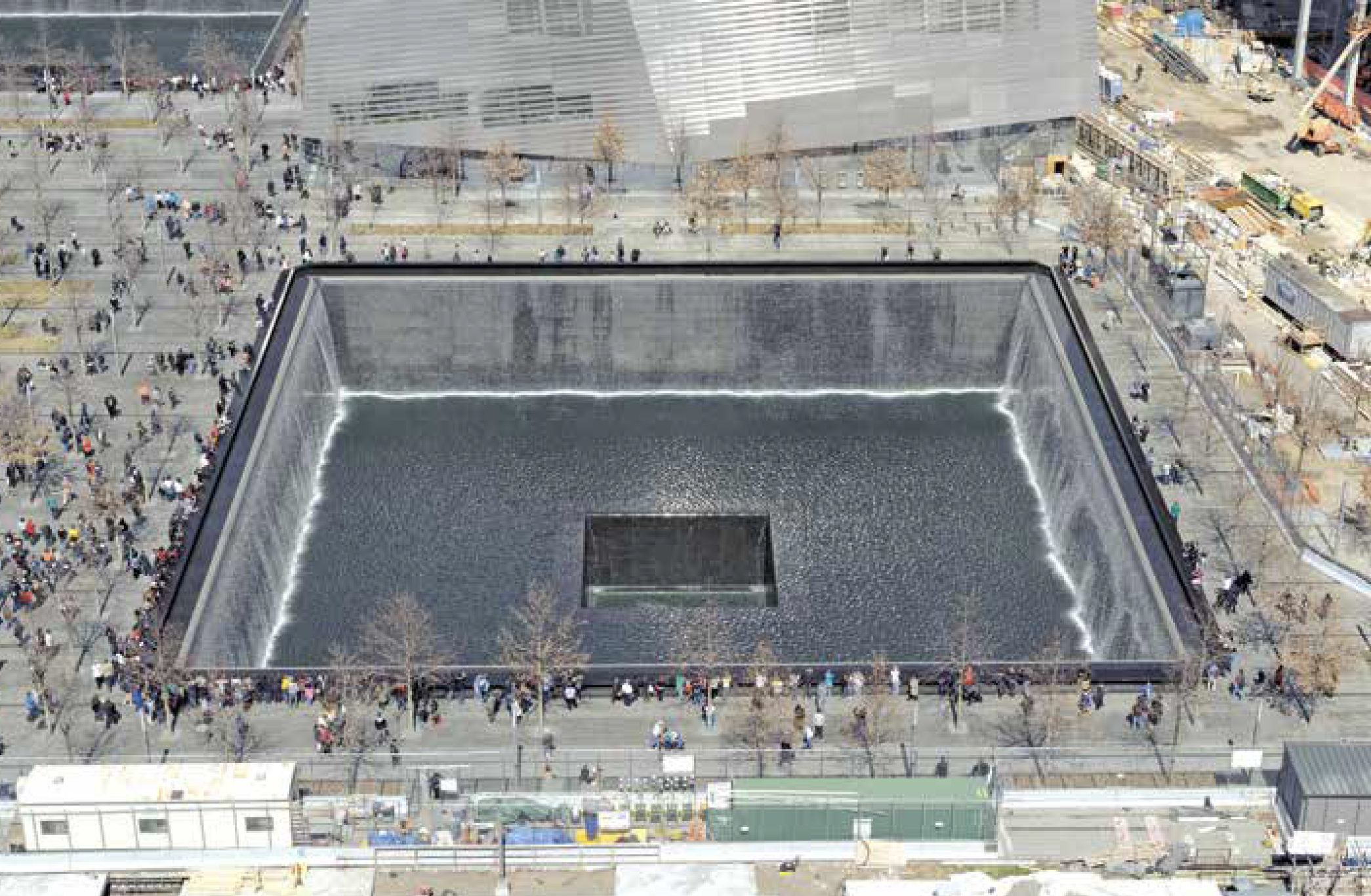

The World Trade Center memorial (WTC) in New York City contains two enormous fountains which presented many waterproofing challenges.

The contractor team spent over 18 months installing the concrete waterproofing system that was selected for the job. Here are the methods utilized:

The Application Method

The entire installation was performed by hand, using squeegees, trowels, and rollers. The project team agreed that these methods would be the most efficient for a successful installation.

An alternative method of application considered was to spray-apply the waterproofing materials. Application of polyurethane materials by airless spray can create airborne particulates which can be hazardous to nearby workers and occupants of adjacent properties. The spray equipment can also, be difficult to operate and maintain in subfreezing temperatures. The greatest advantage to spray equipment is ease of application on vertical and overhead surfaces.

The Surface Preparation Method

Due to a variety of substrates, conditions, and access, workers employed various methods to prepare the surface for coating. They abraded surfaces using hand and power tools, abrasive blasting, shot blasting, and water blasting.

- Concrete surfaces required a profile equivalent to ICRI CSP 4-6 (the International Concrete Repair Institute’s concrete surface profile)

- Steel surfaces needed an SSPC SP-10 (the Society for Protective Coatings’ Surface Preparation guideline) with a minimum 2- to 3-mil profile.

These requirements are standards for surface roughness and cleanliness. ICRI CSP 4-6 is equivalent to a light-to-medium scarification for systems that are 50 mils (1/8 in.) or more in thickness. SSPC SP-10 is a level of cleanliness for steel with no mill scale, loose material, coatings, and less than 5% staining.

Waterproof Membrane Installation

Installation of the waterproof liquid membrane actually began well before construction of the memorial pools. The first structure to receive waterproofing was the fire-protection water storage tanks in 2005.

Construction of the pools took several years to complete, and, in March of 2009, they were ready to be waterproofed.

KJC Waterproofing began the installation on the lowest portion of the North Pool. Per the specification, a total of 120 dry mils of product were to be applied. The contractor chose the trowel-grade products for the walls and self-leveling products on the floor. Inspection of the waterproofing confirmed minimum thickness had been achieved with an average of 150 dry mils on all surfaces of the lower void of the North Pool.

The contractor then proceeded to apply the waterproof membrane on the main portion of the pools, the walls, and the floors of the upper pools. First, the bottom four feet of the upper pool walls were coated with the trowel-grade material in a single coat. The material was extended onto the floor from 12-18”. This was subsequently combined with the self-leveling material which was applied to the floor. Following this, the upper portions of the walls were then sealed.

The floors consisted of large, open, horizontal spaces. A portion of the floor was built using precast concrete planks. The planks contained several joints that needed special treatment prior to installing the 120-mil layer of waterproof membrane. The self-leveling and trowel-grade materials were used to create slip joints in these areas before the floor was flood-coated.

Also, the floor was marked off in a grid to assure that each five-gallon unit of waterproofing material covered the correct dimensions resulting in a minimum thickness of 120 dry mils. Installers applied the material with squeegees covering around 10,000 square feet per day depending on access to the fountain.

The two-part waterproofing system cured overnight to form a tough, durable, rubber lining. The following day, workers were able to work on the membrane without damaging it. Construction materials could be moved onto the membrane, clearing space in the pool so the next portion of concrete could be coated.

Materials stored on the membrane included insulation and pallets of heavy marble panels that were eventually placed over the membrane to create the finished surface of the pools. The weight of these pallets did not damage the tough polyurethane membrane.

Another Challenge

Another crucial issue the team faced was how to address sealing around several thousand support brackets supporting the marble panels to the walls. It was not feasible to install the brackets before installing the waterproof membrane, so the team decided on a process whereby the contractors sealed around the brackets after they were installed. They abraded two to three inches of the membrane around each bracket, treated the area with a bond enhancer, and sealed it with a caulkable version of the trowel-grade material.

Also Read: Don’t Let Environmental Conditions Ruin Your Next Coating Project

The final portion of the installation took place at the top of the pools. Workers applied waterproofing under the plates that display the names of all the victims of the September 11, 2001, extending four feet down to the interior vertical wall. Within the troughs there are adjustable, stainless steel weir plates that create an unbroken cascade of water into the upper pool. The weir plates needed to be able to be adjusted after the membrane was installed to fine-tune the shape and flow of the falling water. In order to create a seamless seal between the concrete and stainless steel plates, a combination of the waterproofing material and a preformed joint from Situra Inc. was used.

C.I.M. Industries tested the compatibility of the waterproofing material with the joint material and assisted in the design of the moving joint, which consisted of several layers of the waterproofing material, reinforcing fabric, and a preformed joint system.

Opposite the weir on the exterior of the troughs, contractors had to combine the waterproofing materials with a hot rubber system used to seal the memorial park. Contractors used a multilayer detail consisting of the fountain waterproofing material, uncured neoprene, and hot rubber. This particular detail contained numerous layers to provide waterproofing redundancy at this critical juncture (Figure 4).

Figure 4 – Hot rubberized asphalt waterproofing on plaza that surrounds each fountain ties into the two-part urethane used to seal each of the pools.

Other particulars, such as tie-ins to penetrations, drains, and conduit—were kept to a minimum. With the exception of the water supply pipes and drains, all penetrations in the fountains were kept above the service levels of the pools. Penetrations occurred above the water level and then branched down, concealed by a nameplate parapet and stone cladding where they were needed within the pools. Where penetrations did exist below the water level, trowel-grade material was used to form a self-terminating seal to prevent water intrusion in these areas (Figures 5 and 6).

Figure 5 – Plates surround the fountain with the names of the victims. There are numerous penetrations through the waterproofing to provide the heating and cooling for the plates.

Figure 6 – Troughs and penetrations are hidden from view behind horizontal marble panels. The waterproofing system ties into the stainless steel weirs, which are fully adjustable to control the flow of water into the fountain.

The entire application was repeated in the South Pool. During the installation, the waterproof membrane was exposed to all four seasons. Temperatures ranged from freezing winter conditions to hot and humid summer days. The membrane was performed in a similar range of temperatures.

Inspection & Monitoring

The design team, manufacturer, and third-party inspection team worked together to closely monitor the installation of the waterproof membrane system. To assure that the membrane was was monolithic and had no leaks, examiners utilized several inspection techniques throughout the project including: high-voltage testing on vertical portions of the fountains, low-voltage testing on horizontal portions, and visual inspections of all areas of the project.

Also read: Documenting Your Coating Application Is Important!

Frequently, the top cause of premature failure of a waterproof membrane is poor adhesion; field adhesion tests were conducted for the duration of the installation to assure that a minimum of 15-pli adhesion was achieved. In most cases, the adhesion far exceeded the minimum requirement, exhibiting cohesive failure in the substrate or the membrane (the desire failure mode). Any deficiencies in the coating were repaired as work progressed from day to day.

In order for other trades to complete their work on the fountains in time for the tenth anniversary of 911, the installation of the waterproof membrane had to meet an early 2011 deadline. The contractor completed work in the spring of 2011, and the memorial opened on schedule on September 11, 2011.

The oldest portions of the waterproofing installation are nearly 17 years old; other many areas of the pools have passed the five-year mark. There have been no reported leaks. The waterproofing system is expected to last a lifetime, as designed.

Click here if you want to learn more about the products used on this project.